A Comprehensive Guide To Industrial Hose Fittings

Industrial hose fittings play a crucial role in fluid transfer systems, ensuring secure connections between hoses and other equipment. From hydraulic applications to chemical processing, these fittings are designed to withstand high pressure, extreme temperatures, and corrosive environments. Choosing the right hose fitting enhances operational efficiency and safety, making them essential in various industries.

For businesses seeking high-quality industrial hose fittings, Alkun Steel stands as a trusted supplier, providing durable and performance-driven solutions tailored to diverse industrial needs.

What Are Industrial Hose Fittings

Industrial hose fittings are essential mechanical components that serve the crucial purpose of connecting hoses to various types of equipment, pipelines, or even other hoses. These fittings play a significant role in regulating fluid flow, preventing leaks, and ensuring the overall integrity and safety of industrial fluid systems. Maintaining proper connections helps optimize performance and enhance the efficiency of fluid transfer processes in various applications.

Hose fittings are available in a wide array of materials, such as stainless steel, brass, and aluminium, each selected based on specific application needs and industry requirements. Stainless steel fittings are renowned for their durability and resistance to corrosion, making them ideal for harsh environments. Brass fittings, on the other hand, are valued for their strength and resistance to wear, while aluminium fittings are often favored for their lightweight and cost-effective properties.

Furthermore, the design of these fittings can vary significantly, including options like threaded, barbed, or quick-connect styles, allowing for versatility in assembly and compatibility with different hose types. This variety makes industrial hose fittings integral to a multitude of sectors, such as manufacturing, automotive, and plumbing, where reliable fluid management is paramount.

Where Are Industrial Hose Fittings Used

- Oil and Gas:

Oil and gas pipelines are critical infrastructures that facilitate the transportation of fuel, chemicals, and various other liquids across vast distances. These pipelines operate under high-pressure conditions, which are essential for maintaining the flow and integrity of these materials during transit. The effectiveness of oil and gas transportation systems can contribute significantly to energy efficiency and economic stability. - Manufacturing:

In the manufacturing sector, pneumatic and hydraulic systems play a vital role in enhancing productivity and operational efficiency. These systems rely heavily on specialized hoses and pipes to transmit fluids necessary for powering machinery, controlling movement, and performing a variety of processes. Without these systems, factories and processing plants would face significant challenges in maintaining their workflows. - Construction:

In construction, hoses are indispensable for multiple applications, including concrete pumping, water delivery, and the operation of heavy machinery hydraulics. High-pressure hoses are utilized to ensure that concrete is poured efficiently and precisely, while water hoses are critical for site preparation and sanitation. Heavy machinery also depend on hydraulic systems to operate effectively, underscoring the importance of reliable piping and hose systems in achieving construction goals. - Automotive & Aerospace:

The automotive and aerospace industries rely heavily on fluid systems to function correctly, where hoses are integral to cooling, lubrication, and fuel supply systems. These systems must maintain high standards of reliability and safety, as they are crucial for ensuring the performance and longevity of vehicles and aircraft. Any failure in these systems can lead to unsafe conditions and operational inefficiencies. - Food & Beverage:

In the food and beverage sector, maintaining sanitary conditions during fluid transfer is paramount. Specialized hoses facilitate the safe and efficient movement of liquids during food processing, ensuring compliance with health standards. This is particularly vital in the dairy industry, where leak-proof systems are necessary to prevent contamination and ensure high-quality products. - Pharmaceutical & Chemical Industries:

In the pharmaceutical and chemical industries, safe handling and processing of materials are critical to maintaining product integrity and safety. Specialty hoses and equipment are designed to be leak-proof, handling hazardous chemicals securely and efficiently. The importance of these systems cannot be overstated, as any leaks or failures could pose serious health and safety risks to workers and consumers alike.

Different Types Of Hose Fittings

- Camlock Fittings

Camlock fittings are a type of quick-release coupling that are specialized connectors that allow for rapid and secure hose connections, making them an essential component in various applications, particularly in the chemical and petroleum industries. These couplings enable users to connect and disconnect hoses quickly without the need for tools, which is crucial in environments where efficiency and safety are paramount. In the chemical industry, where hazardous materials are often handled, the ability to quickly disconnect hoses can prevent spills and enhance safety measures. Similarly, in the petroleum sector, where time is of the essence, quick-release couplings facilitate faster operations in transporting fuels and other substances, thereby optimizing workflow and reducing downtime. Overall, the use of quick-release couplings contributes significantly to improving operational efficiency and safety standards in these critical sectors. - Hydraulic Fittings

Hydraulic fittings are specifically engineered to endure extremely high pressure, making it an essential component in a variety of heavy machinery and hydraulic systems. Its durability and resilience under strenuous conditions allow for reliable performance in demanding industrial applications, ensuring safety and efficiency in operations where pressure levels are critical. - Compression Fittings

These are designed to provide a tight seal without the need for welding or threading, making it an ideal choice for various applications. It is widely used in the distribution systems of both gases and liquids, ensuring secure connections and preventing leaks. Its ease of installation and reliability have made it a preferred solution in many industries, enhancing safety and efficiency in operations. - Barbed Fittings

Barbed fittings include ridged edges designed specifically for the purpose of securing hoses using clamps. This design is particularly beneficial in low-pressure applications, where maintaining a secure connection is essential for optimal performance. The ridges enhance grip and stability, ensuring that hoses remain firmly in place, reducing the risk of leaks and ensuring safety during operation. - Quick-Connect Fittings

The quick-connect fittings enable the rapid attachment and detachment of equipment, thereby significantly reducing downtime in industrial operations. This capability contributes to enhanced efficiency and productivity by minimizing interruptions and facilitating quicker maintenance protocols.. - Threaded Fittings

Threaded fittings are specialized components that utilize a series of grooves and threads to create a secure and reliable connection between pipes or other fittings. These fittings are designed to offer strong, leak-proof connections that are ideal for high-pressure environments, ensuring that systems can operate safely and efficiently without the risk of leaks or failures. The durability and strength of threaded fittings make them a preferred choice in various applications, including industrial, commercial, and residential plumbing, as well as in gas and oil pipelines where pressure integrity is crucial. - Flanged Fittings

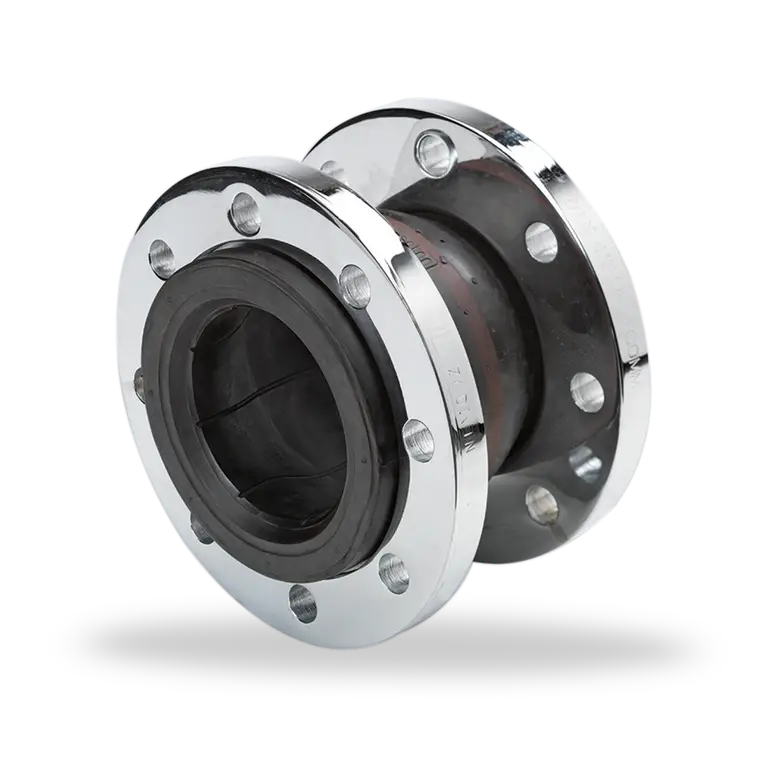

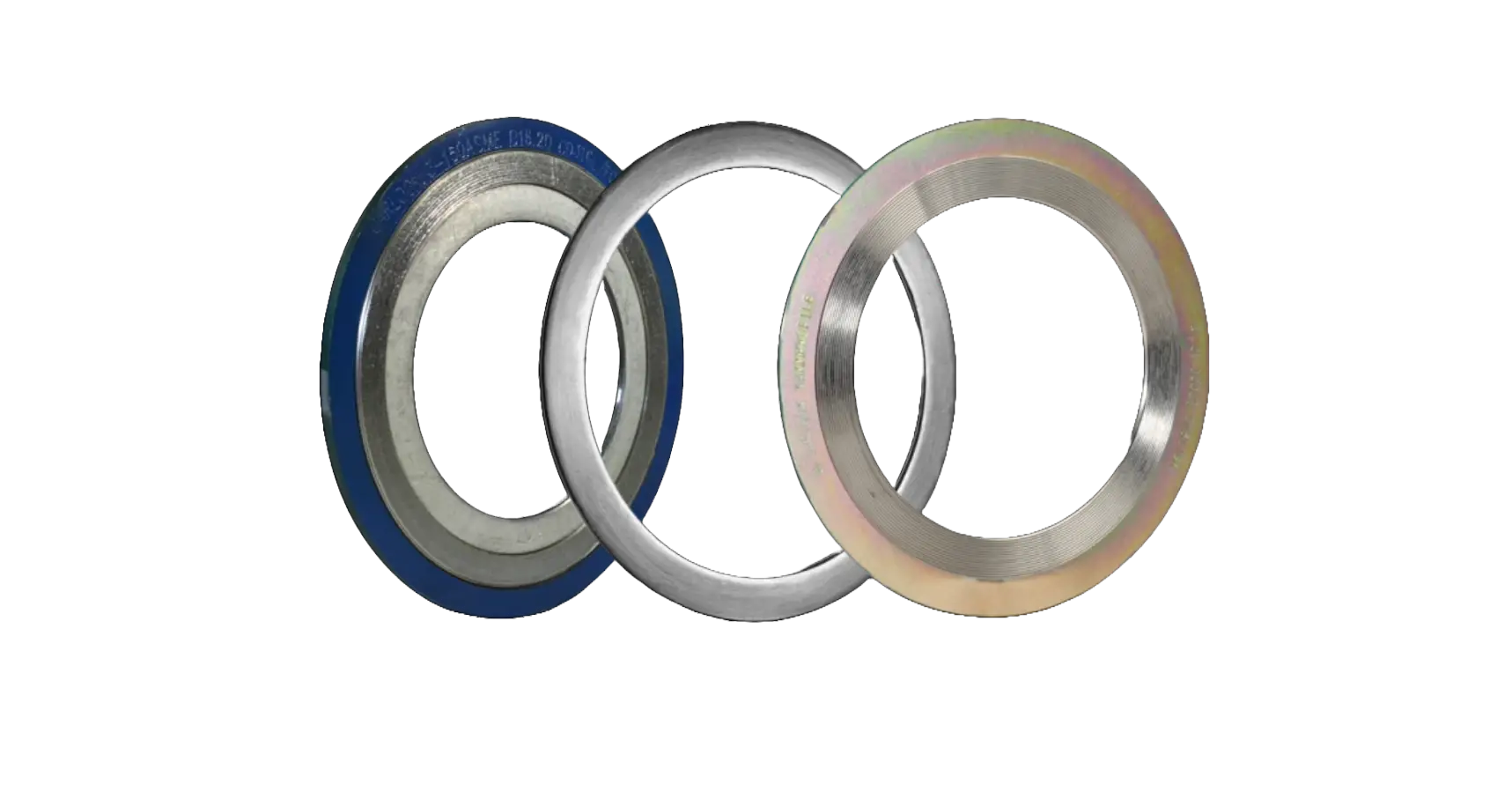

Flanged fittings are integral components in large-scale piping systems, widely utilized across various industries such as oil and gas, water treatment, and chemical processing. These fittings consist of two flanged ends that are bolted together with a gasket in between to create a secure, leak-proof connection. They are designed to withstand high pressure and temperature, making them durable and reliable for long-term usage. By utilizing flanged fittings, engineers can ensure easier assembly and disassembly of piping systems, facilitating maintenance and modifications when necessary.

Advantages Of Hose Fittings

- Leak Prevention: Ensures secure and tight connections, reducing the risk of fluid leakage.

- Enhanced Safety: Proper fittings prevent hose failures, protecting workers and equipment.

- Improved Efficiency: Facilitates smooth and uninterrupted fluid flow, optimizing industrial processes.

- Corrosion Resistance: High-quality fittings resist rust and chemical reactions, increasing durability.

- Versatility: Available in various materials and designs to suit different applications.

- Ease of Maintenance: Quick-connect and compression fittings allow easy replacements, minimizing downtime.

Conclusion

Industrial hose fittings are an essential component of fluid transfer systems across multiple industries. Selecting the right type enhances efficiency, safety, and reliability in operations. Whether it's for hydraulic applications, chemical processing, or food-grade systems, investing in high-quality fittings ensures long-term performance and reduced maintenance costs.

For those looking for premium industrial hose fittings, Alkun Steel provides a wide range of solutions tailored to meet industry standards and application-specific requirements. With a commitment to quality and reliability, Alkun Steel remains a trusted partner for industrial fluid handling solutions.