The Role Of Butterfly Valves Vs. Ball Valves In Fluid Control Systems

In fluid control systems, selecting the right valve is crucial for ensuring efficiency, reliability, and safety. Butterfly valves and ball valves are two of the most commonly used types, each offering distinct advantages depending on the application. While butterfly valves are known for their compact design and quick operation, ball valves provide excellent sealing and durability.

For industries requiring high-quality fluid control solutions, Alkun Steel offers a wide range of valves designed to meet the demanding requirements of oil & gas, manufacturing, and water treatment applications.

What Are Butterfly Valves

A butterfly valve is a type of quarter-turn valve that regulates fluid flow using a rotating disc. The disc is mounted on a central shaft and turns 90 degrees to open or close the flow. Butterfly valves are lightweight, cost-effective, and ideal for large-diameter applications. They are commonly used in HVAC systems, water treatment plants, and chemical processing industries.

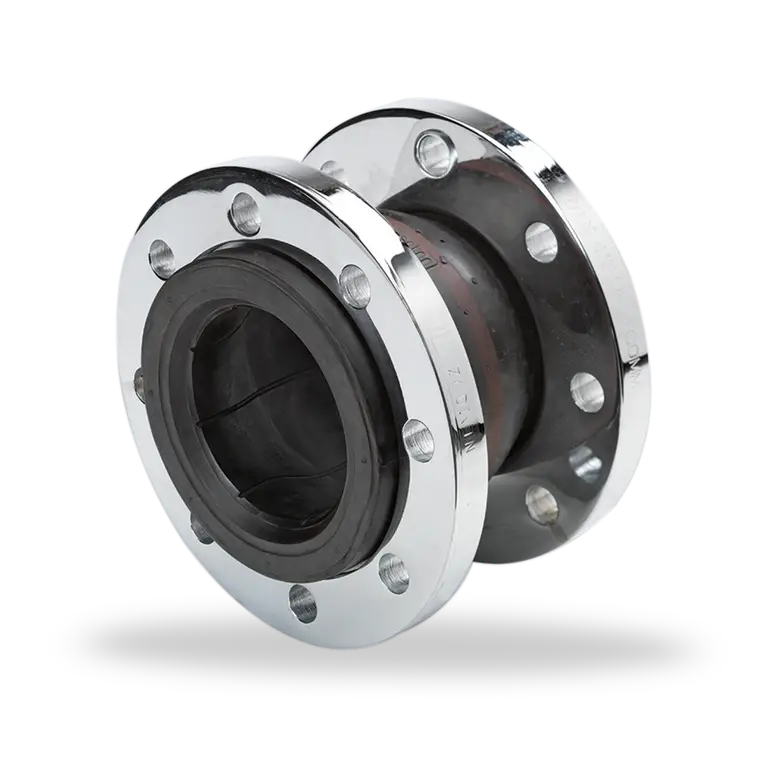

What Are Ball Valves

Alt Tag: Ball Valves Available At Alkun Steel

A ball valve is another quarter-turn valve that controls fluid flow using a rotating ball with a hole through its center. When the ball is aligned with the pipeline, the valve is open; when turned perpendicular, it closes the flow. Ball valves are known for their tight sealing capabilities, durability, and ability to handle high-pressure applications. They are widely used in petrochemical, pharmaceutical, and industrial process systems.

Advantages Of Butterfly Valves

- Compact and Lightweight: Requires less space and is easier to install compared to other valves.

- Cost-Effective: More affordable, especially for larger pipeline systems.

- Fast Operation: Quick quarter-turn movement for efficient flow control.

- Lower Pressure Drop: Offers minimal resistance to fluid flow, improving efficiency.

- Suitable for Large Diameter Applications: Commonly used in pipelines with wide diameters.

Advantages Of Ball Valves

- Excellent Sealing Capability: Provides a tight shut-off to prevent leaks.

- Durability: Resistant to high pressure and temperature fluctuations.

- Minimal Wear and Tear: The ball design reduces friction, increasing longevity.

- Versatility: Available in different materials and configurations for various applications.

- Low Maintenance: Less prone to corrosion and mechanical failures.

Uses Of Butterfly Valves

- Water distribution and wastewater treatment plants.

- Fire protection systems and HVAC applications.

- Food, beverage, and pharmaceutical processing.

- Chemical industries for handling corrosive fluids.

Uses Of Ball Valves

- Oil and gas pipelines for high-pressure applications.

- Power plants and steam systems.

- Petrochemical and refining industries.

- Industrial automation systems requiring precise flow control.

The Difference Between Butterfly Vs Ball Valves

- Design: Butterfly valves use a rotating disc to regulate flow, while ball valves have a spherical ball with a hole that controls the flow by rotating 90 degrees.

- Size Suitability: Butterfly valves are ideal for large-diameter pipelines, whereas ball valves are better suited for small to medium-sized pipelines.

- Sealing Ability: Ball valves provide a tight shut-off with minimal leakage, making them ideal for high-pressure applications. In contrast, butterfly valves offer moderate sealing capabilities.

- Pressure Resistance: Ball valves are designed to handle high-pressure and high-temperature environments, whereas butterfly valves are more suitable for low to medium-pressure applications.

- Cost: Butterfly valves are more cost-effective, especially for large-scale installations, while ball valves tend to be more expensive due to their design and material requirements.

- Durability: Ball valves have a longer lifespan with minimal wear and tear, while butterfly valves may require more maintenance in certain conditions.

Which To Use Where

When selecting a valve for your project, it's crucial to understand the specific requirements of your application. For projects that involve large-diameter pipelines or operate within low-pressure conditions, a Butterfly Valve is often the ideal choice. These valves are not only cost-effective, making them suitable for budget-sensitive projects, but they also provide excellent flow regulation and are easier to maintain. Their design ensures that they can handle substantial volumes of fluid with minimal pressure drops, making them efficient for a variety of systems.

On the other hand, when dealing with high-pressure and high-temperature environments, a Ball Valve is recommended due to its robust performance characteristics. Ball Valves are designed to provide a tight shut-off, which is essential in conditions where preventing leaks and maintaining system integrity are critical. Their spherical design allows for quick opening and closing, offering excellent flow control while minimizing turbulence. This makes them particularly effective in situations where reliability and safety are paramount.

Conclusion

Both butterfly and ball valves play essential roles in fluid control systems, each excelling in specific applications. The choice between the two depends on factors like pressure requirements, sealing needs, cost considerations, and system design.

For businesses looking for reliable and high-performance valves, Alkun Steel offers a diverse selection of industrial valves, ensuring efficiency and durability in various fluid control systems. Whether you need butterfly valves for large-scale operations or ball valves for precision control, Alkun Steel provides trusted solutions for all industries.