Asbestos Vs Non-Asbestos Gaskets: Difference And Uses

Gasket Materials: Overview

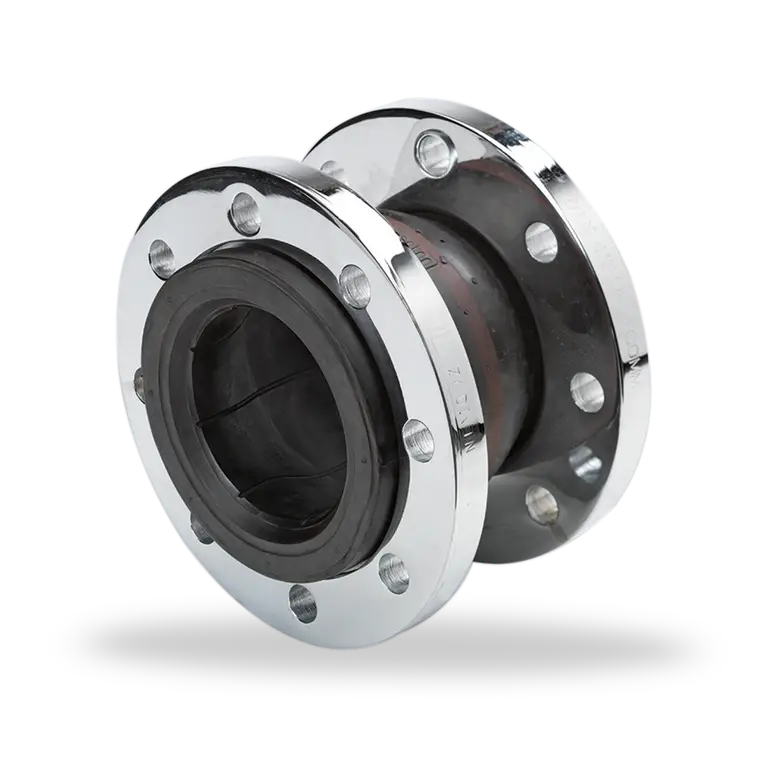

Gaskets are mechanical components used as sealants to prevent the leakage of any fluids or gases that flow along the many industrial gadgets like pipes, pumps, valves, etc. The vast manufacturers and suppliers of the piping and fitting industry rely on Gaskets for cementing the gaps between two mating surfaces. These may be available in various materials, sizes and shapes, depending on your needs. However, the primary intention behind its usage is to ensure a leak-free and seamless flow of the matter. In situations when two mating surfaces are exposed to vibrations, movement or changing temperatures, these sealants come in handy!

As mentioned, these come in a range of materials. Asbestos and Non-Asbestos Gaskets, out of the many materials, are debatable. As an experienced and credible supplier of gaskets in UAE, we sigh to share more valuables on this protracted discussion:

What is an Asbestos Gasket?

Before knowing its characteristics, here's a comprehensive understanding of what it actually is. An asbestos gasket is formed using asbestos fibres. Asbestos is a naturally occurring mineral, which is the primary element of these gaskets. Conventionally, these became very popular in the pipping and fitting industries because of their heat resistance, sustainability, and insulating features. Additionally, these also showed chemical-resistant properties. Popularly employed in diverse industries, these asbestos gaskets were the primary choice for many serving industries.

What is an asbestos gasket used for?

In the past, asbestos gaskets were widely used across diverse industrial applications due to their remarkable heat resistance and durability. They were favoured for their ability to create dependable seals, particularly in demanding conditions characterized by high temperatures and pressures. Typical applications encompassed the fields of boilers, steam pipes, pressure vessels, exhaust systems, automotive engines, and various industrial machinery.

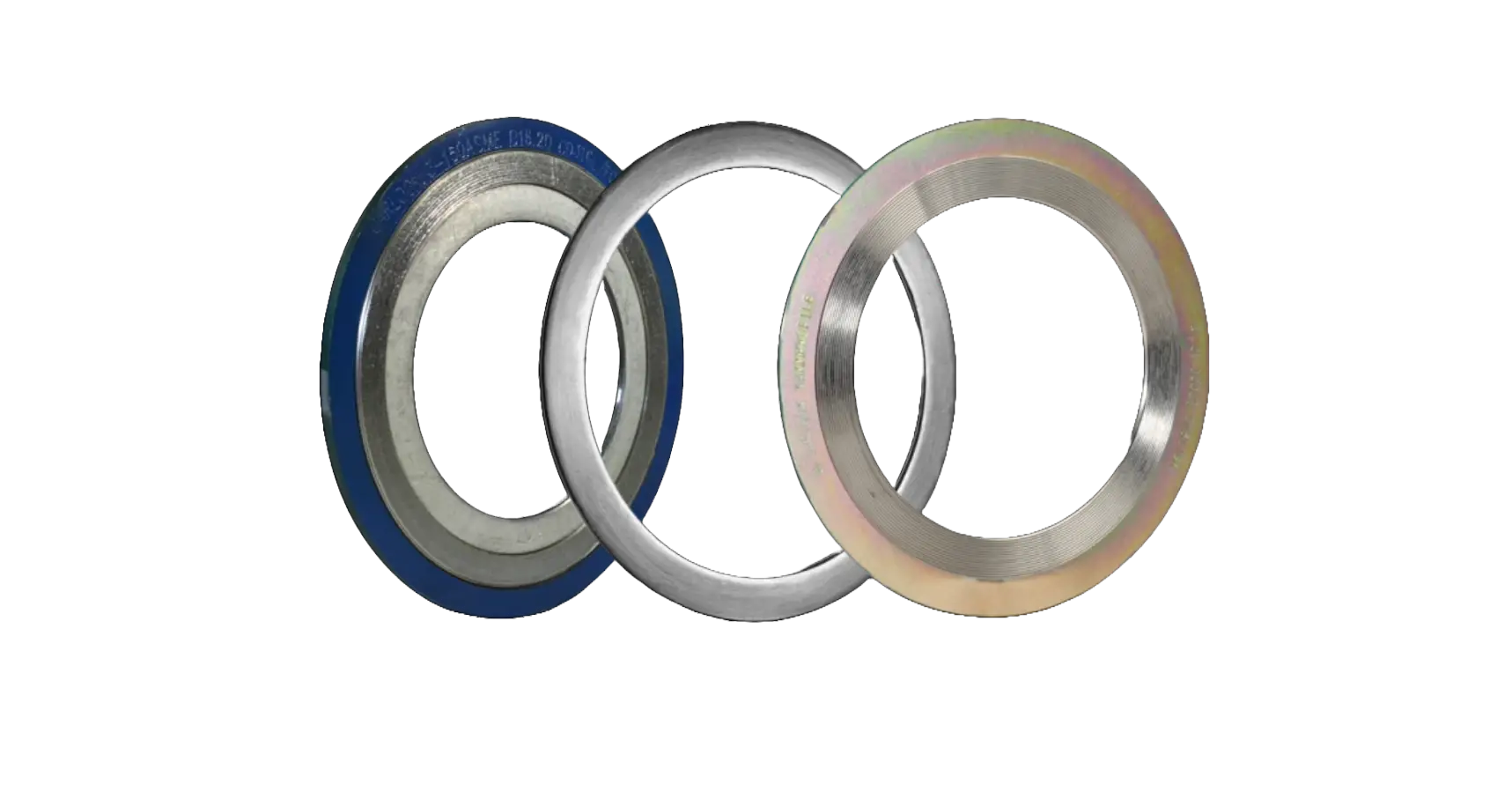

What Is Non -Asbestos Gasket?

Non-asbestos gaskets are changing the dynamics of these sealants. These have become increasingly popular in various industries. As the name says, these are typically made of non-asbestos materials, mainly synthetic fibres like graphite, fibreglass, etc. One major reason behind their popularity is their blending potency with rubber and other binding materials. Apart from this, these synthetically formed gaskets are also highly safe, effective, and versatile.

What is a non-asbestos gasket used for?

Non-asbestos gaskets play a significant role in various industries, with extensive applications in piping and fitting systems, engines, and boilers. They are crucial for creating strong seals that prevent the leakage of fluids or gases, thereby maintaining the integrity of the systems. In the context of engines, these gaskets are essential for withstanding high temperatures and pressures while sealing critical components like cylinder heads and exhaust manifolds. In the chemical processing sector, non-asbestos gaskets serve a vital purpose in equipment exposed to corrosive chemicals, including pumps and reactors. Their reliable sealing capabilities also benefit hydraulic and pneumatic systems when gaskets made from materials like PTFE are used, ensuring efficient operation.

Asbestos VS Non-Asbestos Gasket: The Difference

Here are some key differences that help you select better:

- Heat Resistance:

- Asbestos Gaskets: In comparison to the modern gasket material type, these conventional gaskets are more capable of handling heat waves.

- Non-Asbestos Gaskets: Although it cannot match the previously used gasket type, it can do justice to many industries which does not involve enormous heat exposure. Here, it all depends on the materials used.

- Sealing Property:

- Asbestos Gaskets: These gaskets are immensely effective in areas exposed to higher temperatures and higher pressures.

- Non-Asbestos Gaskets: These, too, serve justice when it comes to its efficiency. Almost both these types have efficient sealing performance.

- Safety:

- Asbestos Gaskets: Asbestos is frequently associated with serious health risks when its fibres are released into the air and inhaled. This is one of the major reasons why non-asbestos gaskets become extremely demanding.

- Non-Asbestos Gaskets: Non-asbestos gaskets are considered a safer alternative, as they do not pose the same health hazards associated with Asbestos.

- Composition:

- Asbestos Gaskets: Asbestos gaskets are primarily composed of asbestos fibres, leveraging the natural mineral's heat-resistant and durable properties.

- Non-Asbestos Gaskets: In contrast, non-asbestos gaskets are crafted without Asbestos as a primary component and are instead fabricated from a variety of alternative materials.

Asbestos and Non-Asbestos Gasket: Which is better?

In the tug between Asbestos and non-asbestos Gaskets, the better one is the one that fits your application requirements. Although non-asbestos gaskets have been primary in many industries, Asbestos serves its own importance in areas of higher pressures and temperatures. Depending on your industrial needs and requirements, the gaskets are put to use. To avoid any fluster and for righteous fittings, it is always recommended to obtain these from credible gasket suppliers.

Related Articles

Brass Vs. Aluminium Camlocks: Choosing The Right Material For Your Application

Read MoreExploring the expansion of steel production in GCC and other emerging nations

Read MoreHow Structural Steel Helped The Majestic Architectures Around The World - Part 3

Read MoreHow Structural Steel Helped The Majestic Architectures Around The World - Part 2

Read MoreHow Structural Steel Helped The Majestic Architectures Around The World - Part 1

Read MoreAllowable & Galvanized Iron Pipe Fittings – Trusted Name For All The Pipe Fitting Needs

Read More