Everything You Need To Know About Grooved Pipe Fittings

Overview:

In the world of piping and fittings systems, grooved pipe fittings have become an essential component. These fittings are known for their versatility, ease of installation, and reliability in joining pipes together. Whether you are a seasoned professional or a DIY enthusiast, understanding grooved pipe fittings can be invaluable for various applications. In this comprehensive guide, we'll delve into everything you need to know about grooved fittings, from their history to their applications and advantages.

The concept of grooved fittings dates back to the early 20th century when Captain Ernest Tribe, an engineer in the British Royal Navy, developed the first grooved coupling. His invention aimed to simplify and expedite the pipe joining process, especially in shipbuilding. Over the years, the design evolved and found its way into various industries, including fire protection, HVAC, and plumbing.

How do groove fittings work?

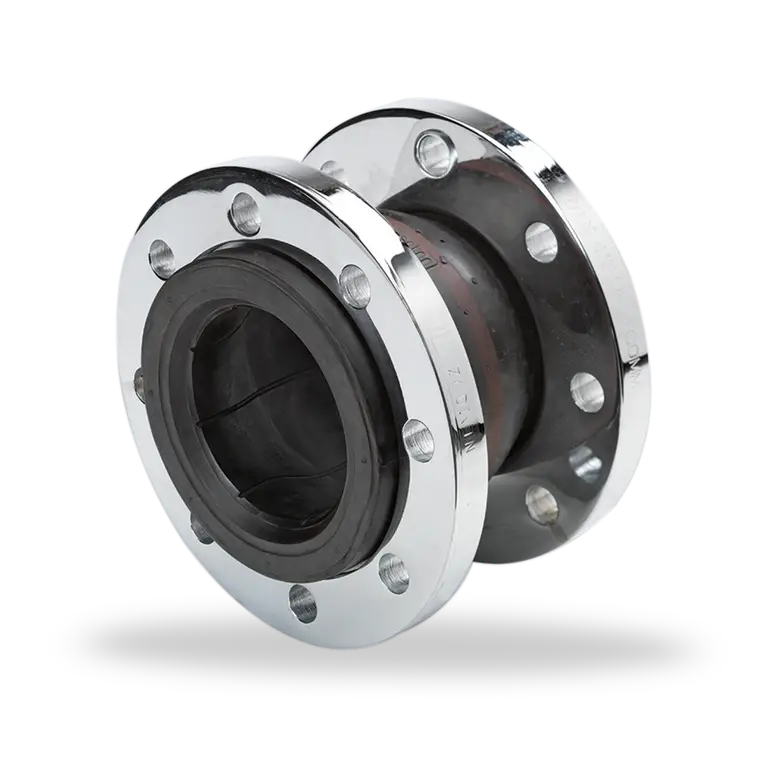

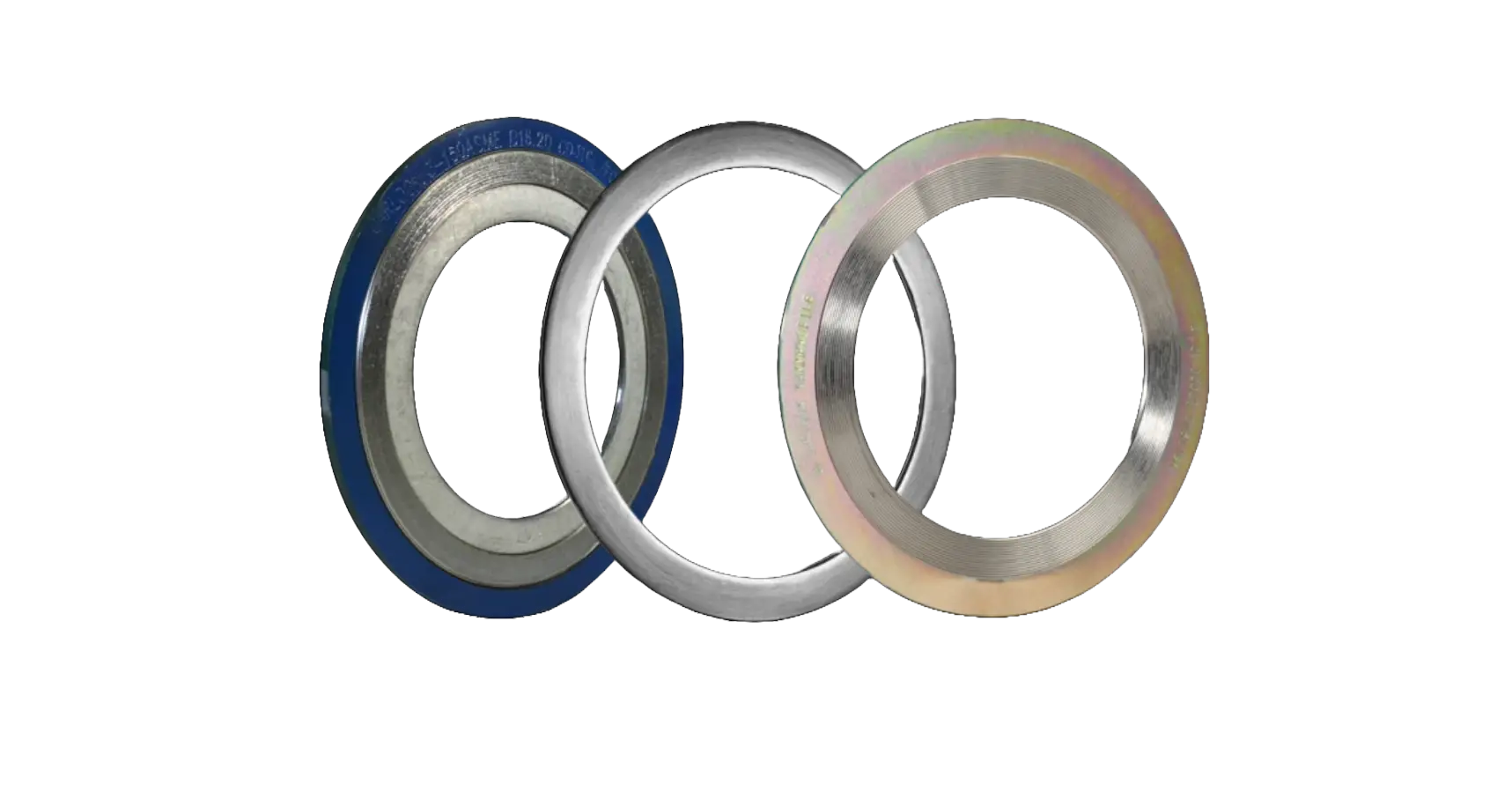

At the core of grooved pipe fittings' functionality is the groove itself. Pipes are prepared by grooving, which involves cutting a groove into the pipe ends. The grooves are usually semi-circular or U-shaped. Then, the grooved ends of the pipes are fitted with gaskets and inserted into the grooved fittings. A coupling housing, typically made of ductile iron or other durable materials, is secured around the joint using bolts and nuts. This compresses the gaskets, creating a tight seal and effectively joining the pipes.

What are the types of grooved fittings?

Grooved fittings are available in a wide range of materials to suit various applications. Common materials include ductile iron, stainless steel, and aluminium. Each material has its unique properties, making it suitable for specific environments and industries.

There are several types of grooved fittings, including:

- Couplings: These are used to connect two grooved pipe ends. They come in rigid and flexible versions, with the latter allowing for some degree of movement.

- Elbows: Grooved elbows are used to change the direction of piping. They are available in different angles, such as 45 degrees and 90 degrees, to accommodate various layouts.

- Tees: Tees are used to create branches in a pipeline, allowing the flow of fluids in multiple directions.

- Reducers: Reducers are used to transition between pipes of different sizes. They can be concentric (reducing in diameter uniformly) or eccentric (reducing while maintaining one side at the same level).

- Adapters: Grooved adapters allow you to connect grooved pipes to other types of pipes, such as threaded or welded pipes.

What are the types of grooved fittings?

Grooved fittings offer several advantages that have contributed to their widespread adoption:

- Ease of Installation: Installing grooved pipe fittings is significantly quicker and more straightforward than traditional welding or threading methods. This reduces labor costs and downtime.

- Flexibility: Grooved Pipe & Fittings can accommodate thermal expansion and contraction, making them suitable for applications where pipes may expand and contract due to temperature changes.

- Reliability: When properly installed, grooved fittings provide a leak-tight and durable connection. They are also resistant to vibration, which is crucial in some industrial settings.

- Versatility: Grooved fittings can be used with a variety of pipe materials, including steel, stainless steel, copper, and plastic. This versatility makes them suitable for a wide range of applications.

Applications of Grooved Fittings

- Grooved fittings find applications in various industries and sectors:

- Fire Protection: Grooved fittings are commonly used in fire protection systems to connect sprinkler pipes. Their reliability and ease of installation are critical in emergencies.

- HVAC Systems: Heating, ventilation, and air conditioning systems often utilize grooved fittings for their ease of installation and flexibility.

- Mining and Industrial: In rugged and demanding environments, grooved fittings provide a dependable solution for conveying fluids and materials.

- Commercial Construction: Grooved fittings are often used in commercial buildings for plumbing, water distribution, and heating systems.

Conclusion:

Grooved fittings have come a long way from their origins in the early 20th century. They have revolutionized the piping industry with their ease of installation, versatility, and reliability. Whether you're working on a fire protection system, an HVAC installation, or an industrial project, understanding grooved fittings is essential for a successful and efficient plumbing system. By obtaining these from credible suppliers, one can easily leverage its potency to the maximum extent.

Related Articles

Brass Vs. Aluminium Camlocks: Choosing The Right Material For Your Application

Read MoreExploring the expansion of steel production in GCC and other emerging nations

Read MoreHow Structural Steel Helped The Majestic Architectures Around The World - Part 3

Read MoreHow Structural Steel Helped The Majestic Architectures Around The World - Part 2

Read MoreHow Structural Steel Helped The Majestic Architectures Around The World - Part 1

Read MoreAllowable & Galvanized Iron Pipe Fittings – Trusted Name For All The Pipe Fitting Needs

Read More