How To Prevent Valves From Corrosion

Corroded Valves: Risks and Hazards

Valves play an indispensable role in regulating the flow of fluids across a wide spectrum of industries, from petrochemical plants to water treatment facilities. Yet, one persistent challenge faced by operators and engineers is the insidious threat of valve corrosion. Valve corrosion can result in diminished efficiency, expensive maintenance, and, at its worst, pose safety risks. In this comprehensive guide, we will delve into the intricate aspects of valve corrosion, its underlying causes, and, more importantly, the proactive steps to prevent it through valve anti-corrosion measures.

What Causes Corrosion on Valves?

To effectively thwart corroded valves, it is crucial to grasp the factors that contribute to this issue. Here are some of the primary causes:

- Moisture: Valves in industrial settings are frequently exposed to moisture, which can significantly hasten the corrosion process. When moisture combines with oxygen, it can lead to the formation of rust on metal surfaces.

- Chemical Exposure: Valves employed in chemical processing plants are especially susceptible to corrosion due to their contact with aggressive and corrosive chemicals. The corrosive combination of chemicals and high temperatures can be exceptionally damaging.

- Gases: Specific gases can be corrosive to valve materials. For instance, hydrogen sulfide (H2S) is notorious for causing sulphide stress corrosion cracking, an extremely severe form of corrosion, in carbon steel valves.

- Temperature Extremes: Extreme temperatures can expedite valve corrosion by accelerating the reaction rates of chemicals and moisture with valve materials. High temperatures can also give rise to stress corrosion cracking.

- Abrasion: Valves can come into contact with abrasive materials in particular applications, such as slurries. This abrasive exposure can compromise protective coatings and expose the valve to corrosion.

Valve Anti-Corrosion Measures

Now that we have established a firm understanding of the common causes of valve corrosion, let's delve into a range of effective valve corrosion prevention measures aimed at ensuring the durability and dependability of your valves.

1.Material Selection: Opting for the right valve material is one of the foundational valve anti-corrosion measures. Depending on the precise application and the types of chemicals or conditions involved, materials like stainless steel, Hastelloy, and Monel are frequently preferred due to their inherent corrosion-resistant properties. The selection of materials should always align with the nature of the process fluid.

2.Protective Coatings: Application of protective coatings is an invaluable defence against corrosion. Several types of coatings, including epoxy, PTFE, and ceramic coatings, create a protective barrier between the valve's surface and corrosive elements. Regular inspection and maintenance of these coatings are pivotal to ensuring their continued effectiveness.

3.Cathodic Protection: Cathodic protection constitutes a corrosion control technique that employs electrical currents to shield metal surfaces from corrosion. Although more commonly used in pipelines, this method can also be applied to valves using either sacrificial anodes or impressed current systems.

4.Regular Inspection and Maintenance: Preventing valve corrosion is an ongoing and dynamic process. Routine inspection and maintenance of valves are critical for promptly identifying and addressing corrosion issues before they escalate into major problems. These measures encompass cleaning, lubrication, and the replacement of damaged components as necessary.

5.Design Considerations: Thoughtful valve design can significantly contribute to corrosion prevention. Features such as proper drainage, the minimization of dead legs, and the selection of the most appropriate valve type for the specific application can all fortify corrosion resistance. Additionally, the design of valves with protective covers or enclosures can shield them from adverse environmental factors.

6.Corrosion Inhibitors: Corrosion inhibitors are chemical agents that can be introduced into the process fluid to mitigate corrosion. They function by forming a protective film on the metal surface, effectively preventing direct contact with corrosive elements. The choice of inhibitor should be tailored to the specific valve application and the characteristics of the fluid.

7.Environmental Control: Exerting control over the environmental conditions in which valves operate is another potent strategy for corrosion prevention. This involves maintaining appropriate humidity levels, temperature control, and the minimization of exposure to moisture and corrosive gases, all of which can appreciably extend the lifespan of valves.

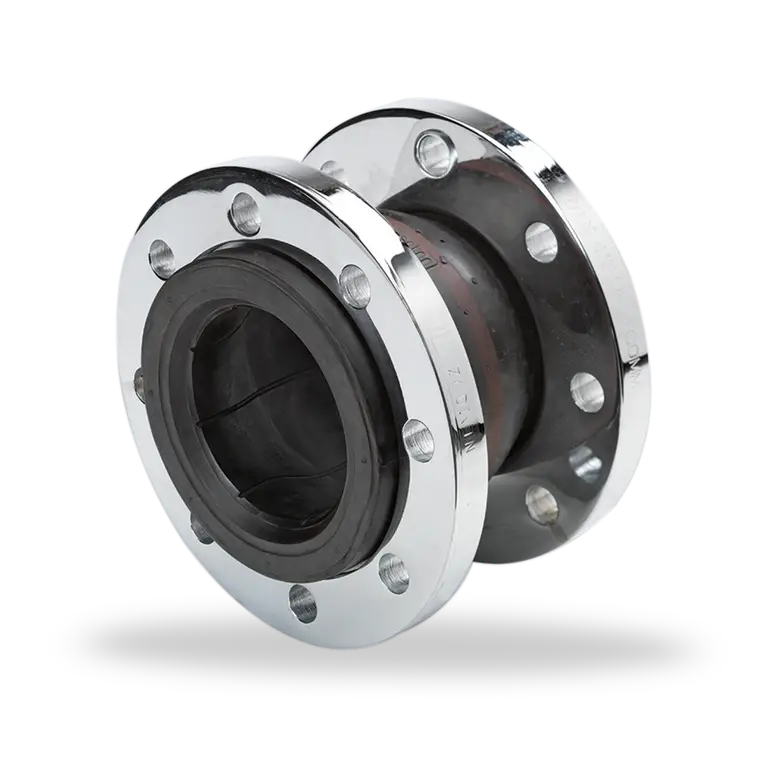

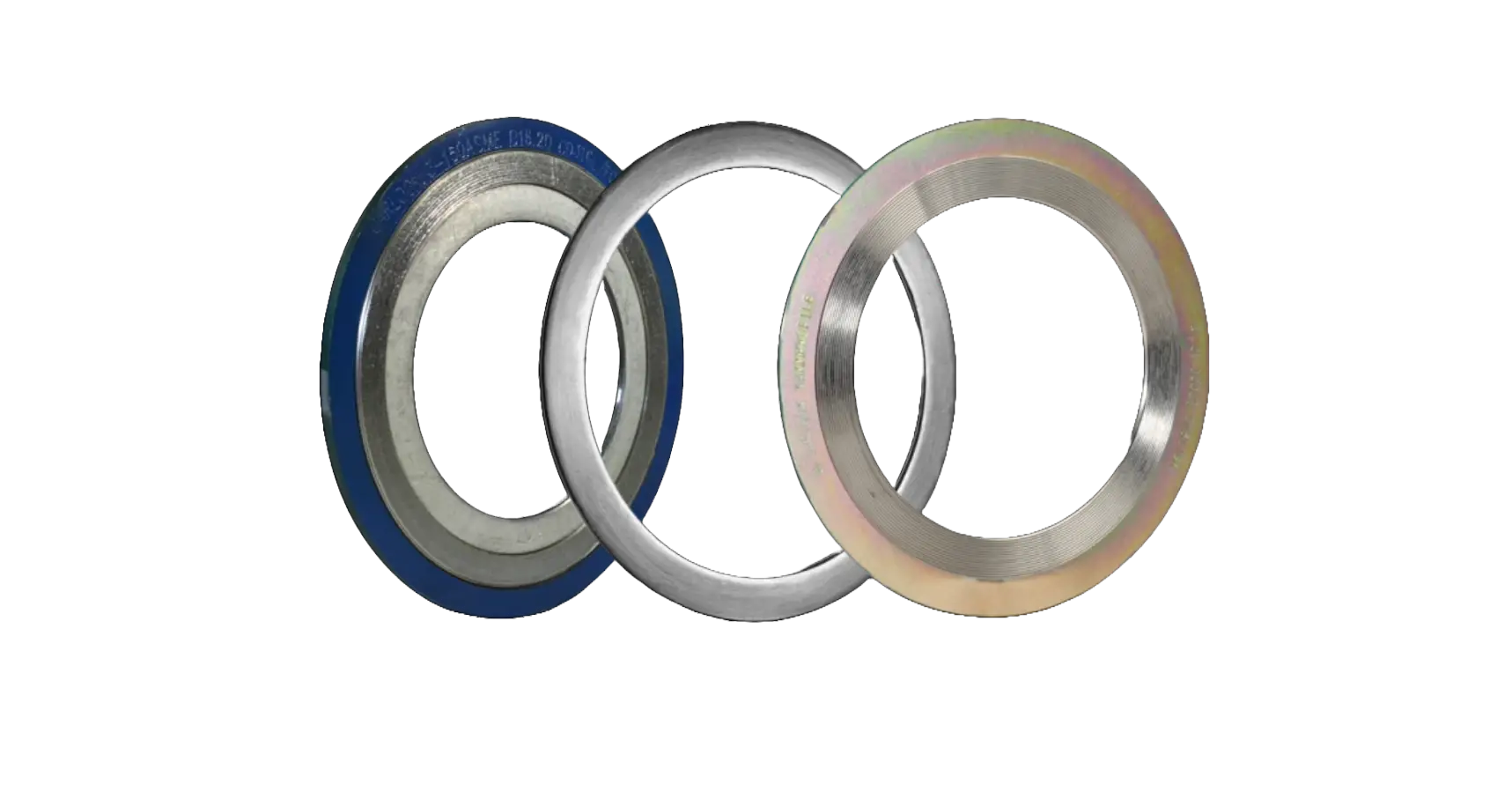

8.Material Compatibility: Ensuring that the materials employed in the valve, including gaskets and seals, are compatible with the process fluid is imperative. Incompatible materials can induce chemical reactions that expedite corrosion. Thoroughly verifying material compatibility is essential to averting this issue.

Conclusion

Valve corrosion remains a formidable challenge across diverse industries, but it is far from insurmountable. By making judicious choices in material selection, applying protective coatings, diligently performing maintenance, and implementing an array of anti-corrosion techniques, you can significantly prolong the life of your valves while mitigating the perils associated with corroded valves.

Preventing valve corrosion is not only pivotal for operational efficiency but is also a cornerstone of safety and environmental preservation. It represents an investment that yields enduring benefits, sparing you from costly repairs, downtime, and potential safety incidents. If you've ever wondered, "How do you prevent valve corrosion?" the answer lies in the proactive adoption of maintenance practices and the integration of the appropriate corrosion prevention measures tailored to your specific application.

Related Articles

Brass Vs. Aluminium Camlocks: Choosing The Right Material For Your Application

Read MoreExploring the expansion of steel production in GCC and other emerging nations

Read MoreHow Structural Steel Helped The Majestic Architectures Around The World - Part 3

Read MoreHow Structural Steel Helped The Majestic Architectures Around The World - Part 2

Read MoreHow Structural Steel Helped The Majestic Architectures Around The World - Part 1

Read MoreAllowable & Galvanized Iron Pipe Fittings – Trusted Name For All The Pipe Fitting Needs

Read More