Fasteners 101: Types, uses and how to choose the right one.

Overview:

The word 'fasteners 'might sound ultra-modern in the first go. But we can assure you a large number of people have unintentionally or deliberately used it in their mundane chores. Being oblivious of the right terminology, we've probably heard it as screws, nuts, heads etc. The term; Fasteners, hidden behind the curtains, entail the integration of various callow terms like screws, bolts, etc. With more light shared on the same, the article below elucidates details on everything you need to know about fasteners. If you are reading this article with the motive to buy one, surely stay hooked till the end, as we've shared tips on choosing the right one for the right use!

What Are Fasteners?

If we abide by the hardware industry, these can be defined as instruments used to secure or link two or more units or components together. Consider the term 'fastener' to be a girdle that confines to various other tools like screws, bolts, etc. We'll dive into the types of fasteners in the next section. For now, in simpler terms, let us understand a fastener as a mechanical tool that is used to secure and join objects together. Despite the many subsets of fasteners, there are 2 major types of fasteners listed above the other subsets. These are;

- Permanent Fasteners: These are mechanical tools that are meant for one-time use. The removal here usually results in damage to the fastener or object they are attached to.

- Non-permanent Fasteners: These are tools that can be reused multiple times. As these are easy to mantle and dismantle, they are widely used in many industries.

What are the different types of fasteners?

Talking about the types of fasteners, there are multiple tools that are integrated. However, listed below are the major subsets used cardinally in the linking and formation of various objects.

1.What are Screws?

Screws serve as threaded connectors featuring a spiral ridge, known as threads, which interlock with a threaded cavity, usually found in a nut or a threaded boss. Their primary purpose is to bind two or more components together by exerting a clamping force. This versatile category includes variations like wood screws, machine screws, and self-tapping screws.

2.What are Bolts?

Bolts bear a resemblance to screws but are predominantly employed in tandem with a nut to fasten and secure multiple elements. They come in assorted forms and sizes, ranging from the hexagonal bolts to the distinctive carriage bolts and the resourceful eye bolts.

3.What are Nuts?

Nuts are internally threaded fasteners meant to be paired with bolts or screws, fostering a robust threaded connection. They come in diverse configurations, such as the utilitarian hex nuts, the winged wing nuts, and the elegant acorn nuts.

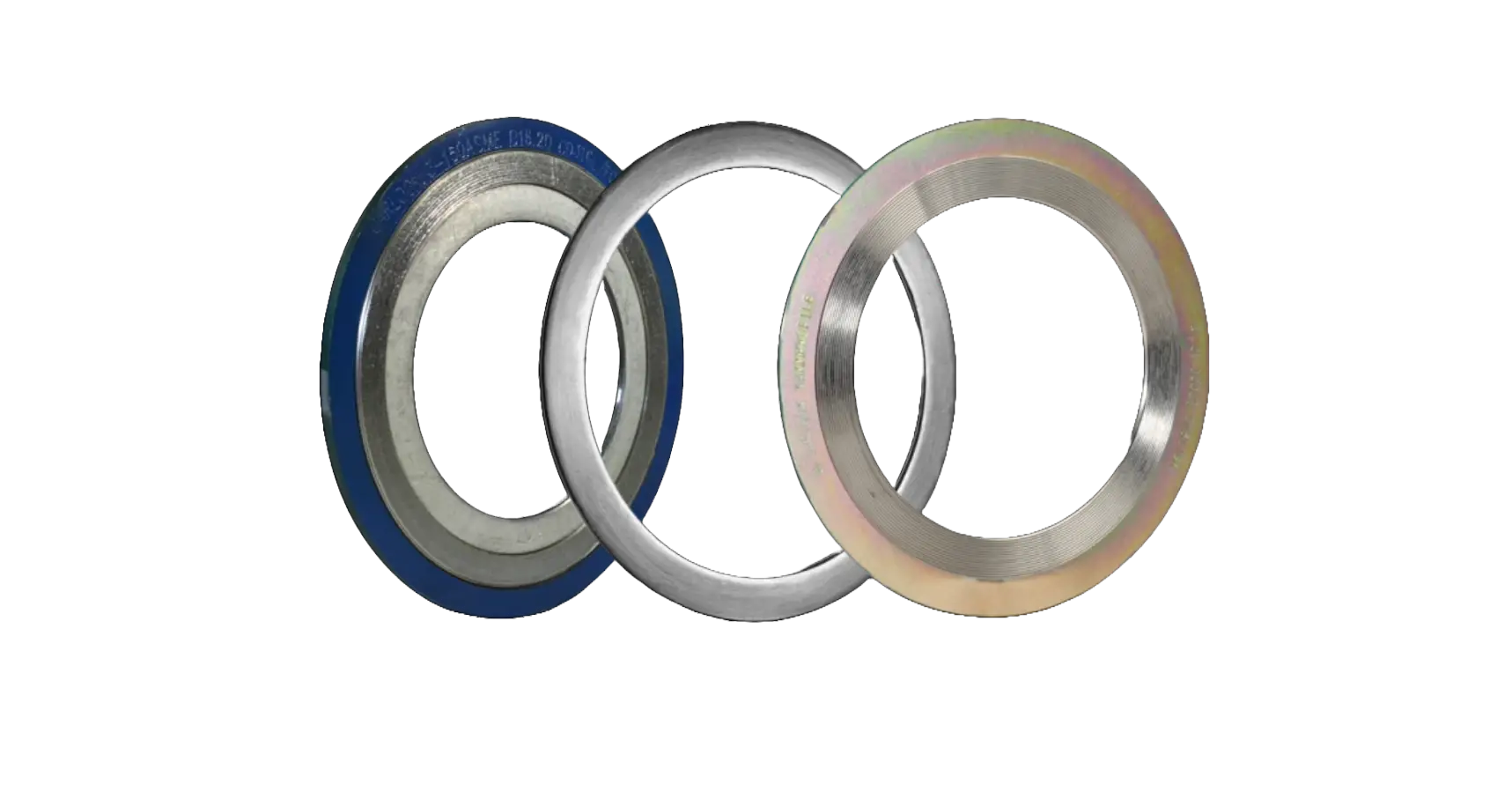

4.What are Washers?

Washers assume the role of thin, flat plates featuring a central aperture. Their mission is to evenly distribute the force applied by a fastener, averting any damage to the surface it secures. Varieties encompass plain washers, securing lock washers, and resilient spring washers.

5.What are Rivets?

Rivets are permanent fasteners customarily employed for uniting two materials, frequently metal or plastic. Their installation method involves deforming the end of the rivet to firmly secure it in place. Within this category, you'll find steadfast solid rivets and concealed blind rivets, both serving as embodiments of enduring connection.

What are fasteners used for?

Listed below are the many fasteners uses:

- The construction and building industry heavily relies on fasteners such as bolts, nuts, screws and anchors. These components are used to connect elements, secure building materials, and assemble scaffolding. In addition to that, concrete anchors and expansion bolts play a role in securing structures to masonry surfaces. Roofing screws and nails are commonly employed to attach roofing materials securely.

- Moving on to the manufacturing and machinery sector, fasteners find use in machinery assembly and various manufacturing processes. They play a role in joining components together. Precision screws and bolts are particularly important when it comes to manufacturing high-precision equipment and machines. Fasteners also play a role in the assembly of conveyor systems, manufacturing lines well and industrial robots.

- In the energy sector, including utilities like power plants or renewable energy installations such as wind turbines or solar panels, fasteners play a role in assembling and maintaining equipment types within these facilities. Specialized types of fasteners come into use within the oil & gas industry for platforms as well as pipelines.

- In the railway and transportation industry, fasteners play a role in the assembly and maintenance of heavy machinery, such as crushers, conveyors and drilling rigs.

- When it comes to food processing equipment and machinery, stainless steel fasteners are commonly used. These fasteners are preferred because they meet the requirements for hygiene and corrosion resistance.

- Fasteners are a component in the assembly of chemical processing equipment as well as pharmaceutical machinery.

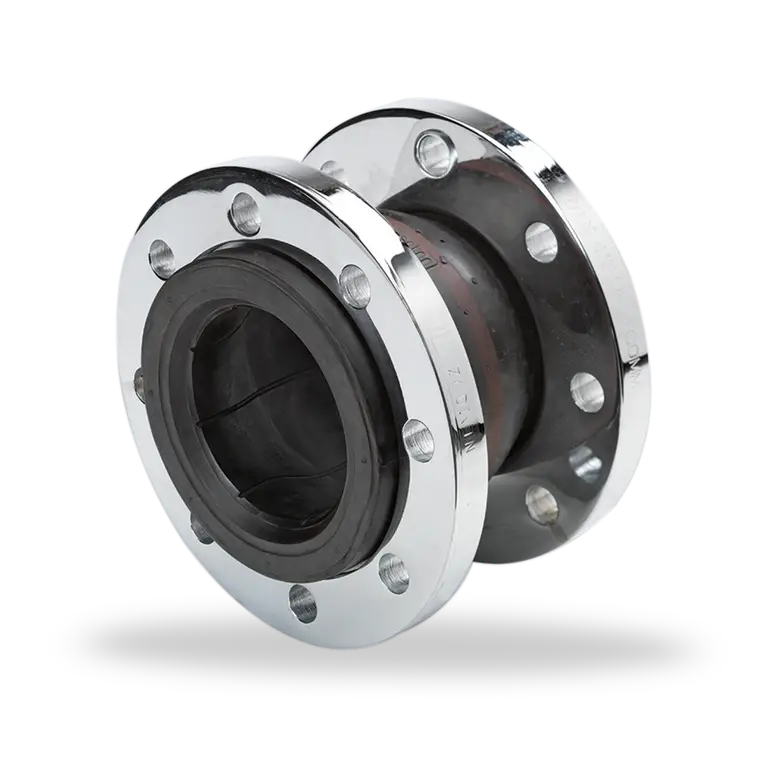

- In piping and fittings, fasteners are utilized to secure pipes, tanks and filtration equipment

How do you choose the right fastener?

The usage of the diverse types of fasteners differs from application to application. Therefore, before buying one, it is important to checklist the following criteria:

1. Know your use: Before the hunt, make sure you know what you are looking for. The design and type should fit in well with your usage in order to avoid any mishaps.

2. Material selection: Keeping your application in mind, select the material that is well-sustainable. Fasteners are built using various components like aluminium, bronze, brass, etc. Generally, carbon steel is the best option. But, according to your application requirement, these materials can differ.

3. Thread selection: Selecting the appropriate thread type is a critical consideration when choosing a fastener, as threads play a pivotal role in the application. Threads come in different varieties, including fine threads (UNF), coarse threads (UNC), and eight-thread configurations, each with its specific characteristics and uses.

4. Exposing factors: Factors like temperature and environment should also be considered during the selection of the right fastener. Using a low heat-resistant material in a high heat-resistant area will do worse than good.

Conclusion:

After having a roundabout at the diversity and functionality of fasteners, let's conclude this Fastener 101 guide. We understand that merely reading an article cannot give you all the valuable insights. But we've got your back! In your hunt for the right fastener, we can be your guide. As the leading supplier in UAE, we serve you quality!

Related Articles

Brass Vs. Aluminium Camlocks: Choosing The Right Material For Your Application

Read MoreExploring the expansion of steel production in GCC and other emerging nations

Read MoreHow Structural Steel Helped The Majestic Architectures Around The World - Part 3

Read MoreHow Structural Steel Helped The Majestic Architectures Around The World - Part 2

Read MoreHow Structural Steel Helped The Majestic Architectures Around The World - Part 1

Read MoreAllowable & Galvanized Iron Pipe Fittings – Trusted Name For All The Pipe Fitting Needs

Read More